When selecting a hook for your hanging wire system, whether it’s for hanging posters, panels, or point-of-sale displays, it’s essential to understand the differences between the various types of hooks available. The right hook not only ensures that your project is secure but also enhances functionality, making adjustments or changes easier when necessary.

In this guide, we give a detailed overview of four different types of hooks, highlighting their features, safe working loads, and the ideal application for each. We also look at the key differences between hooks and loops to help you make the best decision for your project.

A common question when dealing with hanging systems is the difference between a hook and a loop. Although both serve to attach objects, their designs and uses vary significantly.

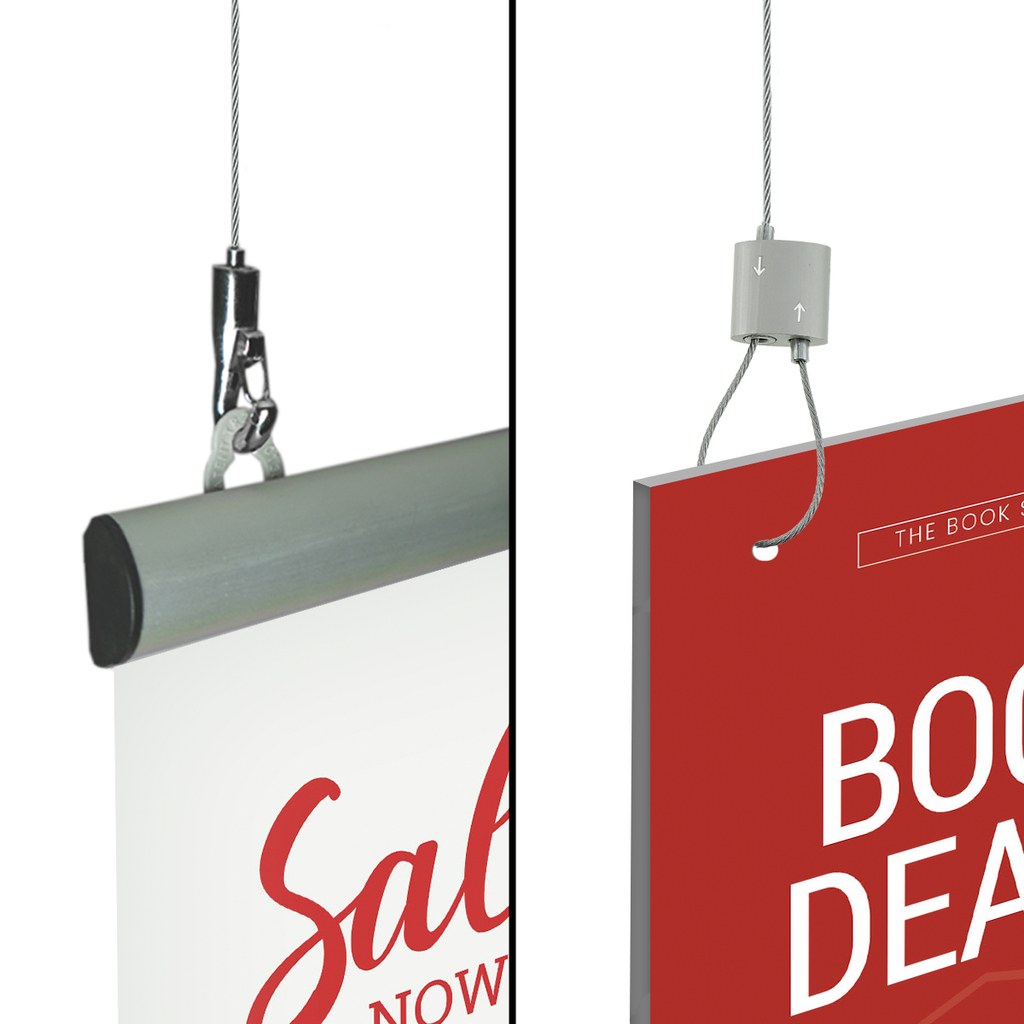

A hook is an open-ended attachment that allows for quick and easy hanging and removal of items. Hooks are ideal for applications where items need to be regularly changed, moved, or adjusted. Their open design makes them highly convenient but also requires caution in some situations, as items can potentially slip off if not properly secured unless the hook has a self-locking mechanism.

In contrast, a loop is a closed attachment point, offering a more permanent solution. Loops are typically used where the load does not need to be frequently removed or adjusted. They provide a secure hold but lack the flexibility of a hook, making them less suited for projects where adjustments are necessary.

The Straight Hook is one of the simplest and most versatile hooks available. It has a large jaw opening which allows for easy hanging and quick changes, making it ideal for situations where flexibility is important. The Straight Hook is often used in environments where items need to be frequently adjusted or replaced, such as retail displays, exhibitions, or art galleries. Being able to easily add or remove items without needing to undo or re-thread the system is a significant advantage.

Despite being easy to work with, the Straight Hook is limited by its safe working load of just 6kg, meaning it’s only suited to light loads. The simplicity of the Straight Hook also means that there is no additional locking mechanism, so while it is convenient, it might not be the best option for locations with heavy foot traffic or where accidental dislodging could be a concern.

If you are working with light objects and need a simple, no-fuss hook, the Straight Hook is a solid choice.

The Safe Hook combines both functionality and a polished appearance, making it a popular choice for when security and style are needed. It has a gated design with a self-locking mechanism which automatically closes once the load is attached. This ensures that the load remains secure, even in areas where vibrations or accidental knocks could dislodge a less secure hook.

With a safe working load of 6kg and compatibility with wire diameters ranging from 1.2mm to 1.5mm, the Safe Hook is great for light- to medium-load applications where safety is a priority. It’s commonly used in commercial interior locations where the combination of aesthetic appeal and functionality is key. The chrome finish adds to its sleek design, making it ideal for visible installations where appearance matters. Whilst it shares the same load capacity as the Straight Hook, the Safe Hook’s self-locking mechanism provides an added layer of security.

The Safe Hook is the preferred option for public spaces or where strict safety standards apply.

The Bee Line Hook stands out due to its adjustability, strength, and cost-effectiveness. With a safe working load of 17kg, it is significantly stronger than both the Straight Hook and the Safe Hook, making it the go-to choice for heavier loads. Its straight-through cable path allows for the addition of extra hooks, enabling ‘daisy-chain’ configurations – great for complex hanging setups or for suspending multiple items from a single cable.

A key advantage of the Bee Line Hook is that it self-locks, much like the Safe Hook but at a lower cost. The Bee Line Hook is durable and practical with a bright silver-coloured finish – not as polished or stylish as the Safe Hook’s chrome finish, but still looks great. This hook is ideal for industrial and commercial locations where strength and security are paramount, but the budget is a concern.

Whether used for suspending signage, artwork, or other heavy items, the Bee Line Hook provides both versatility and strength and is the smart choice for more demanding projects.

The Hook Ended Cable s a versatile solution that combines the strength of wire rope with the convenience of a crimped mini hook on one end. With a safe working load of 20kg, this is the strongest option among the hooks discussed, making it suitable for the heaviest loads. The Hook Ended Cable is often used in industrial, commercial, and even outdoor applications where robustness and reliability are essential, although this hook is not as adjustable as others.

One of the main benefits of this type of hook is its prefabricated design, meaning it comes ready to use with a hook already securely crimped onto the cable. This makes the whole installation process much easier and ensures a strong connect between the hook and wire rope. The Hook Ended Cable is particularly useful when working with heavier items or when a longer-term hanging solution is needed.

The Hook Ended Cable’s strength and ease of use make it a reliable choice for demanding applications.

Choosing the right hook for your project depends on several factors, including the weight of the load, the environment, and the level of security required. Whether you need a straightforward and versatile solution like the Straight Hook, a more secure option like the Safe Hook, a high-strength, budget-friendly choice like the Bee Line Hook, or a more robust solution for heavy-duty applications like the Hook Ended Cable, understanding the differences between these hooks can help you make the best decision.

We have all of these available to buy on their own or a part of a kit on our main website: Sign Holders.